Succeed in your ecommerce business by solving these common order fulfilment problems early on.

Keeping it cool: A survival guide to chilled and ambient fulfilment

Audio reader

.jpg?width=300&name=What%E2%80%99s-Next-for-Demand-Forecasting-blog-advert%20(1).jpg)

Download your copy of the Demand Forecasting eBook

Reviewing predictive analytics, AI, and sustainability in inventory management.

Download the eBookTemperature-sensitive logistics - otherwise known as keeping things cold when they need to be cold and warm when they need to be warm without it all going horribly wrong - is one of eCommerce’s biggest logistical problems.

Whether you’re shipping artisanal cheeses, handcrafted chocolates, or beauty serums that turn to sludge if they get too warm, you’ve got a ticking time bomb on your hands. One minor delay, and your beautifully packaged product arrives somewhere between a soup and a science experiment.

If you’re an eCommerce brand selling chilled and ambient products, you’ll know that getting fulfilment right is non-negotiable. But don’t panic - we’ve got you covered (and not in a load of sludge, thankfully).

This article explores how to nail temperature-sensitive fulfilment, avoid disasters, and keep customers happy, all while ensuring your profits don’t melt away faster than a spray tan in the sun.

Why temperature-sensitive eCommerce is booming

Chilled and ambient goods aren’t just for supermarkets anymore. Thanks to the rise of online grocery shopping, DTC food brands, and beauty and wellness subscriptions, more customers than ever expect delicate, perishable, or temperature-sensitive products to land on their doorstep in perfect condition.

But there’s a catch.

Unlike your standard t-shirt or homeware order, you can’t just slap a shipping label on a wedge of Stilton and hope for the best. If a delivery takes too long, gets left in a warm van, or isn’t stored correctly for even a few hours, the damage is done.

Some key stats to put this into perspective:

- The UK food and drink eCommerce market is worth over $48 billion and growing

- 30% of all online grocery shoppers say they now expect next-day or same-day delivery

- More than half of UK shoppers are now buying perishable items online at least once a month.

The takeaway? Customer expectations are high, and the margin for error is low.

.jpg?width=1500&height=1500&name=half-statistic-uk%20(1).jpg)

The top challenges in fulfilling chilled and ambient goods

1. Keeping things cool (or warm) without going broke

Temperature-sensitive fulfilment is all about cold chain integrity - keeping products within the correct temperature range at all times. The problem? That’s easier said than done.

- Chilled goods need to stay between 0 - 5°C or risk spoiling

- Frozen products require a solid -18°C or below

- Ambient-sensitive goods (think chocolate, wine, and beauty products) must be stored away from extreme heat or cold.

One slight temperature fluctuation, and you’re not just losing stock, you’re losing money.

2. Preventing spoilage and waste

Every business dreads wasted inventory, but for temperature-sensitive goods, spoilage can spiral out of control fast.

- Food waste costs the UK about £19 billion a year

- Up to 12% of perishable eCommerce orders are rejected due to quality issues on delivery

- A single shipping delay can render an entire pallet of stock unsellable.

This means businesses need razor-sharp inventory control, rapid order processing, and packaging that can handle transit delays without catastrophe.

3. Navigating UK food and safety laws effectively

Selling temperature-sensitive goods is more than just a logistical challenge. There are plenty of legal loopholes and hurdles to jump through and over.

Regulatory bodies like the Food Standards Agency (FSA) require businesses to:

- Prove temperature stability throughout the supply chain

- Track and log temperature data in case of a compliance audit

- Ensure labelling and storage instructions meet strict guidelines.

The fines for non-compliance aren’t exactly small, and one bad review about a melted or spoiled product can do serious damage to your brand reputation.

4. Last-mile delivery

Even if you’ve done everything right so far, the biggest risk comes in the final stretch - getting your product from the warehouse to the customer’s doorstep without disaster striking.

The main last-mile challenges include:

- Keeping products at the right temperature during transit

- Delivering fast enough to prevent spoilage

- Tracking shipments in real-time so that if something goes wrong, you can fix it before it’s too late.

And let’s not forget the wildcard factor; couriers who leave packages in direct sunlight, upside down, or in ‘safe places’ that make no sense - like your wheelie bin on bin day.

Top tip: Maintaining product integrity in transit

Even if your chilled or ambient products are stored perfectly in a climate-controlled warehouse, the real test begins the moment they leave the facility.

Unlike standard eCommerce, where a delay might be frustrating, but harmless, even a slight temperature fluctuation can make a perishable product unsellable. And with the UK’s unpredictable weather, the risk of products being left on a doorstep in the sun or exposed to freezing temperatures in winter makes last-mile delivery even trickier.

Best practices to maintain product integrity in transit:

- Specialist courier partnerships - Not all delivery providers can handle chilled and ambient goods. Partnering with couriers who offer temperature-controlled transport, real-time tracking, and trained handlers is essential.

- Smart packaging solutions - Insulated packaging, gel packs, and dry ice help maintain stable conditions, even if delays occur. Some brands are also trialling active cooling technologies, such as phase-change materials, which absorb and release heat to regulate temperature.

- Shock-absorbing packaging - Perishable items, particularly food and pharmaceuticals, can be easily damaged in transit. Using sturdy, tamper-proof packaging prevents breakages while ensuring hygiene and compliance.

- Customer communication and tracking - Giving customers the ability to track deliveries in real-time and opt for time-slot deliveries reduces the risk of packages sitting outside in the wrong conditions.

With the right combination of packaging, logistics partners, and tracking technology, brands can reduce the risk of damaged or spoiled products while maintaining customer trust and satisfaction.

Top tip: Managing regulatory requirements for food and pharmaceuticals

When it comes to temperature-sensitive fulfilment, compliance isn’t just best practice, it’s the law.

UK regulations for food and pharmaceuticals are among the strictest in Europe, and failure to comply can lead to fines, product recalls, and permanent reputational damage.

Key regulations brands need to meet:

- Food Standards Agency (FSA) compliance - Businesses handling chilled and ambient food must follow HACCP (Hazard Analysis and Critical Control Points) principles, ensuring that risks like bacterial growth and contamination are prevented at every stage.

- Temperature monitoring and record-keeping - In the event of an audit, brands must be able to provide a clear temperature log for each product’s journey, from storage to delivery. This means having automated monitoring systems in place.

- Pharmaceutical Good Distribution Practice (GDP) - Any business dealing with medicinal products must adhere to strict temperature controls, security measures, and batch tracking to ensure product safety.

- Packaging and labelling laws - All perishable goods must have clear handling instructions, expiration dates, and tamper-proof seals to comply with UK safety standards.

Disclaimer: Remember, this isn’t an exhaustive list, so make sure you consult a legal professional to get this right.

Ensuring compliance across multiple product categories is complex, and brands often lack the time or infrastructure to manage it in-house. That’s why working with a fulfilment provider that already meets these requirements can save time, cost, and regulatory headaches.

The high costs of temperature-controlled logistics

Running a chilled or ambient supply chain isn’t cheap. Unlike standard fulfilment, where warehouse space and shipping are relatively straightforward, temperature-sensitive logistics come with higher operational costs at every stage.

Where do these extra costs come from?

- Climate-controlled warehousing - Chilled and frozen storage requires specialist refrigeration systems, humidity control, and energy-intensive cooling units, all of which drive up costs.

- Higher packaging expenses - Standard cardboard boxes and packing paper won’t cut it. Brands need insulated materials, cooling packs, and tamper-proof seals to prevent spoilage.

- Expensive last-mile delivery - Not all couriers can handle chilled and ambient goods, and those that do often charge a premium for temperature-controlled transport.

- Stock loss and waste management - Even with the best processes in place, some level of spoilage is inevitable. Unlike standard eCommerce, where a returned item can be restocked, perishable goods must be discarded, meaning lost revenue.

How to manage costs without compromising quality:

- Consolidate fulfilment operations - Using strategic warehouse locations reduces the distance (and cost) of last-mile delivery.

- Optimise packaging - While insulated packaging is necessary, choosing cost-effective yet efficient materials (such as reusable thermal liners) helps keep costs down.

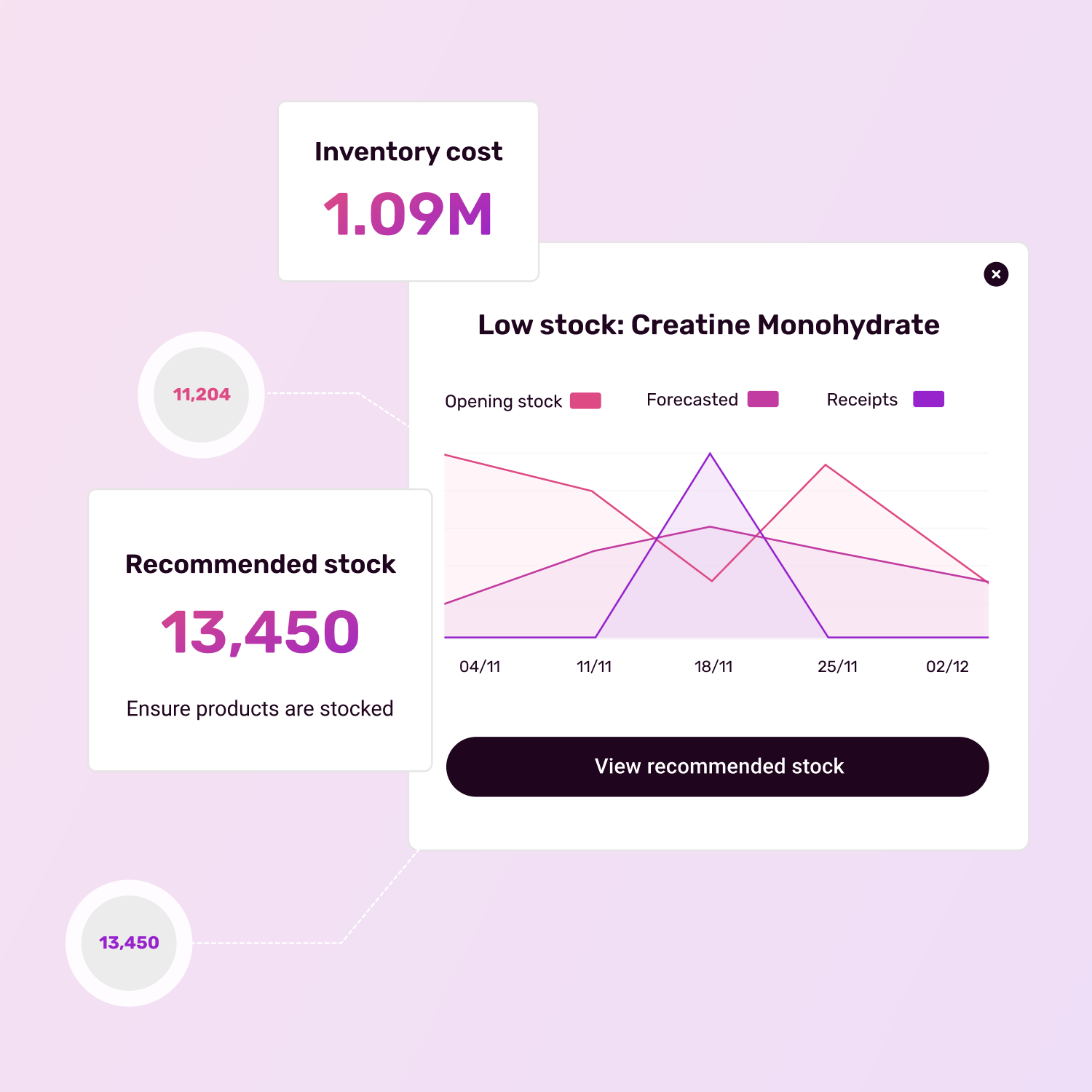

- Automate stock management - Using AI-driven demand forecasting and inventory tracking prevents overstocking and minimises product wastage.

While temperature-sensitive fulfilment will always have higher costs, investing in the right fulfilment strategies can reduce unnecessary expenses and keep profit margins intact.

Best practices for chilled and ambient fulfilment

The brands that succeed in temperature-sensitive logistics don’t leave anything to chance. Here’s how to get it right:

1. Partner with a fulfilment provider who actually knows what they’re doing

Not all fulfilment providers are equipped to handle chilled and ambient goods. Some can barely store a T-shirt properly (meow), let alone a product that requires constant temperature control and rapid turnaround times.

A great fulfilment partner should offer:

- Dedicated climate-controlled storage

- Automated temperature tracking and compliance reporting

- Specialist packaging solutions

- Access to temperature-controlled courier networks

See how we do all of this (and more).

2. Optimise stock management to reduce waste

Temperature-sensitive goods have short shelf lives. You need real-time inventory tracking, FIFO (First In, First Out) stock rotation, and automated expiry date monitoring to make sure nothing goes to waste.

3. Choose the right packaging

You wouldn’t ship a glass bottle without the appropriate protection, so why ship perishable goods without temperature-resistant packaging?

- Insulated boxes and liners to maintain stable temperatures.

- Gel packs or dry ice for extra cooling support.

- Tamper-proof seals to prevent contamination.

4. Use specialist couriers for last-mile delivery

The wrong courier can ruin even the best fulfilment strategy. Work with delivery partners who:

- Offer express shipping for perishable goods

- Have real-time tracking and temperature logging

- Know not to leave dairy products in the sun (we fear this is common sense, but we’re saying it anyway).

How fulfilmentcrowd keeps temperature-sensitive orders under control

Managing chilled and ambient fulfilment requires precision, experience, and the right technology - and that’s exactly what fulfilmentcrowd delivers.

With a network of temperature-controlled fulfilment centres, advanced warehouse management technology, and integrated courier partnerships, fulfilmentcrowd provides:

- Climate-controlled storage solutions for chilled, frozen, and ambient-sensitive goods

- Automated compliance tracking to meet FSA and HACCP regulations

- Ultra-fast picking and packing to get orders out before they spoil

- Seamless omnichannel fulfilment to ensure stock is managed across all sales channels.

When you’re dealing with temperature-sensitive products, there’s no room for error - and that’s why brands trust fulfilmentcrowd to get it right.

View our case study

Want to see how fulfilmentcrowd keeps chilled and ambient goods fresh, compliant, and delivered on time?

View our case studies to learn more about how we help brands master temperature-sensitive logistics.

Looking for more industry insights?

Check out our other recommendations just for you!

See allIntroducing fulfilmentcrowd's latest Fulfilment Network Partner, Fairfield, with our partners Haith's based in Louth, Lincolnshire!

fulfilmentcrowd integrates with both Amazon FBA and FBM! Discover which fulfilment process is the best option to grow your business.

By Alice Davies

By Alice Davies